Welded table

- CategoryClass project

- Project dateJanuary 2024

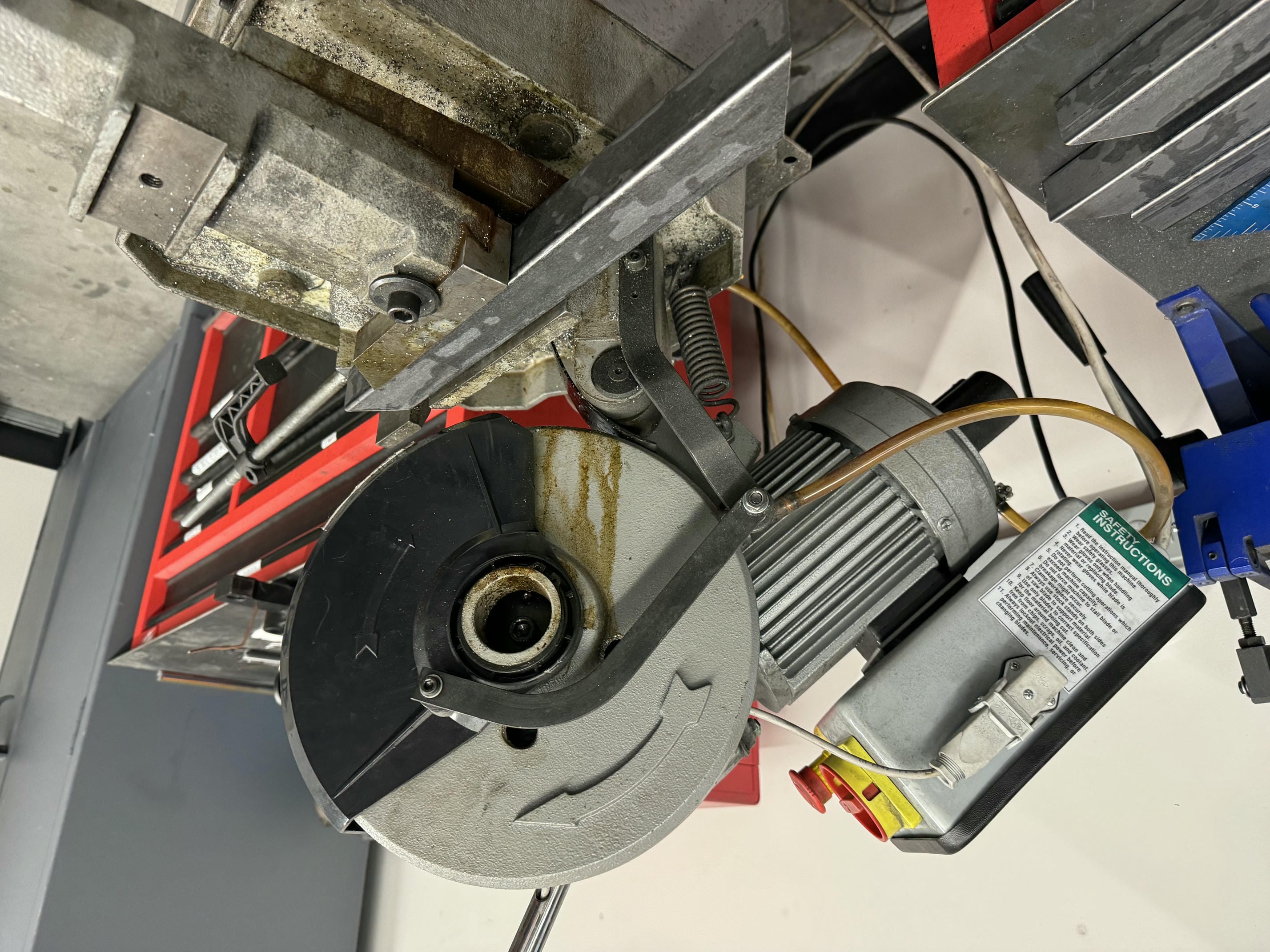

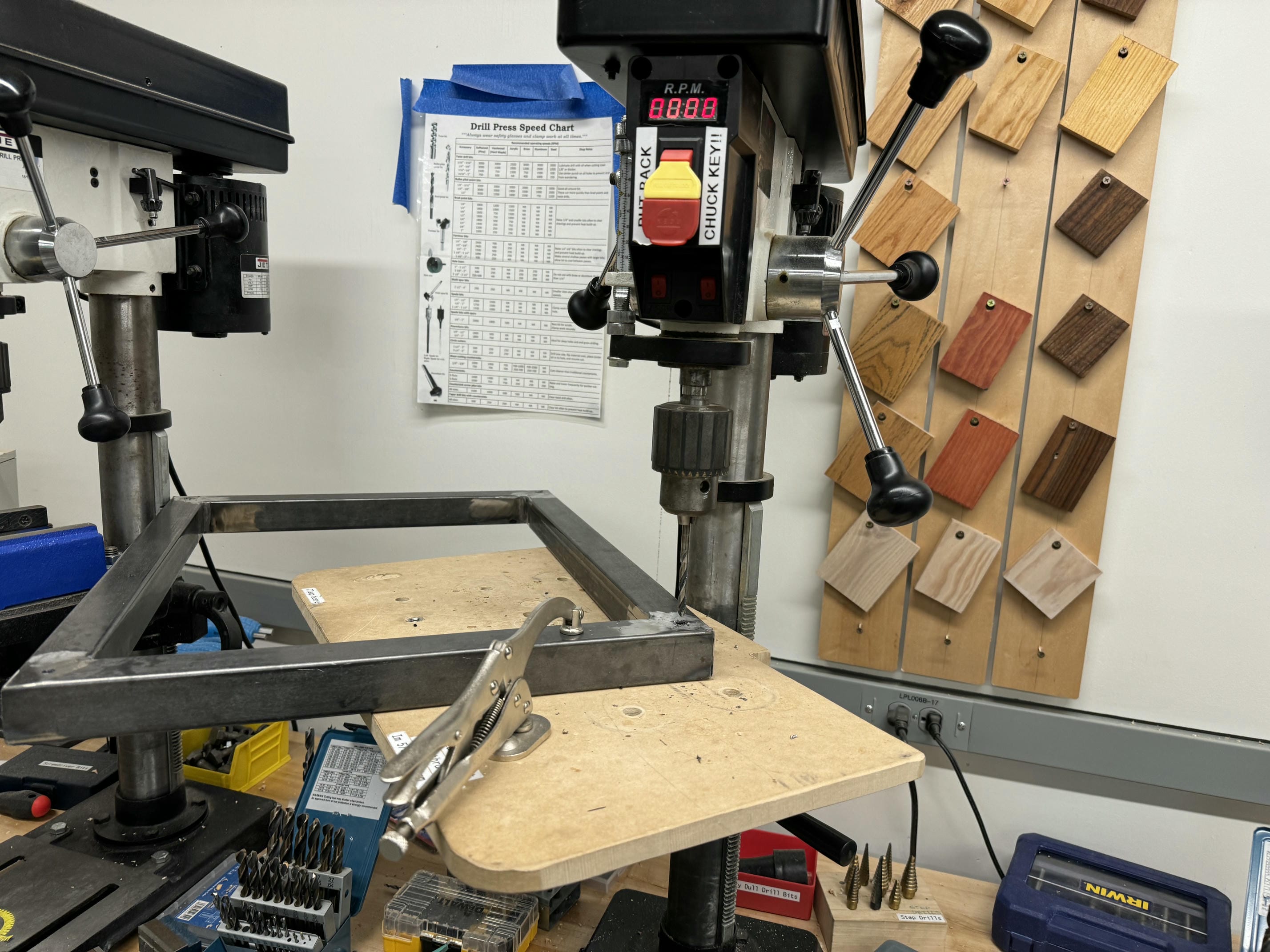

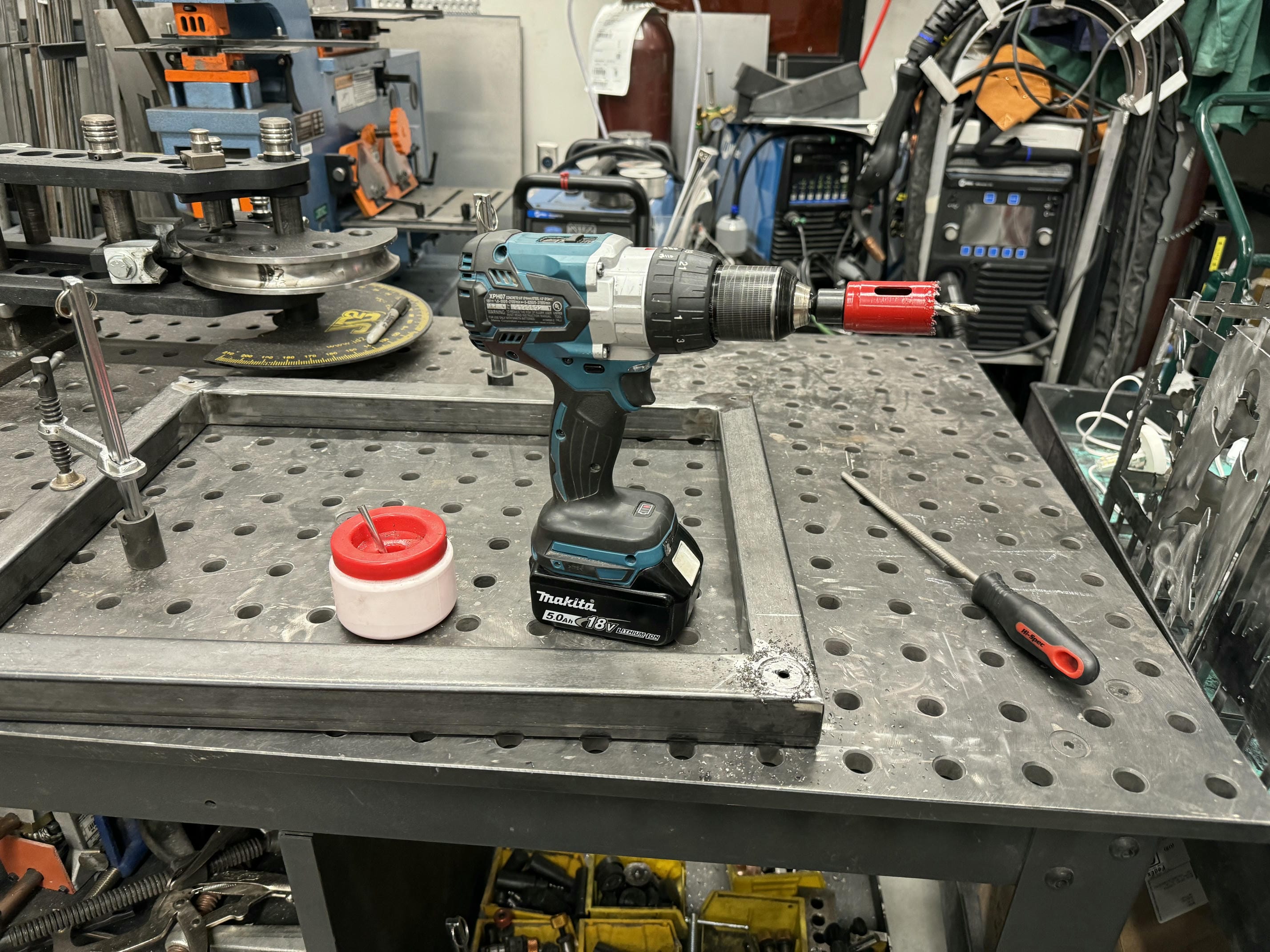

- Skills usedMig welding, cold sawing, portable horizontal bandsaw, angle grinder, drill press, hand drill, chisel

About this project

I took a mig welding workshop, and I decided to weld a table! I wanted the table to look like it was floating using chains. Because I wanted to be able to scoot my legs underneath it as I sat on the couch, I designed it to be a c-shape so I could pull the tabletop in closer than a traditional 4-legged table.

I began by welding the base, which was 1.5" box steel cut at 45-degree angles. Because metals expand when heated, then contract as they cool, I had to be mindful of the order in which I welded each joint. After all the joints were welded, I used an angle grinder to take off the excess welding and polish it flat.

I wanted the whole assembly to be able to roll, I created holes in the base for caster wheels, creating a hole on the top wide enough such that a socket could fit inside to tighten the nut down.

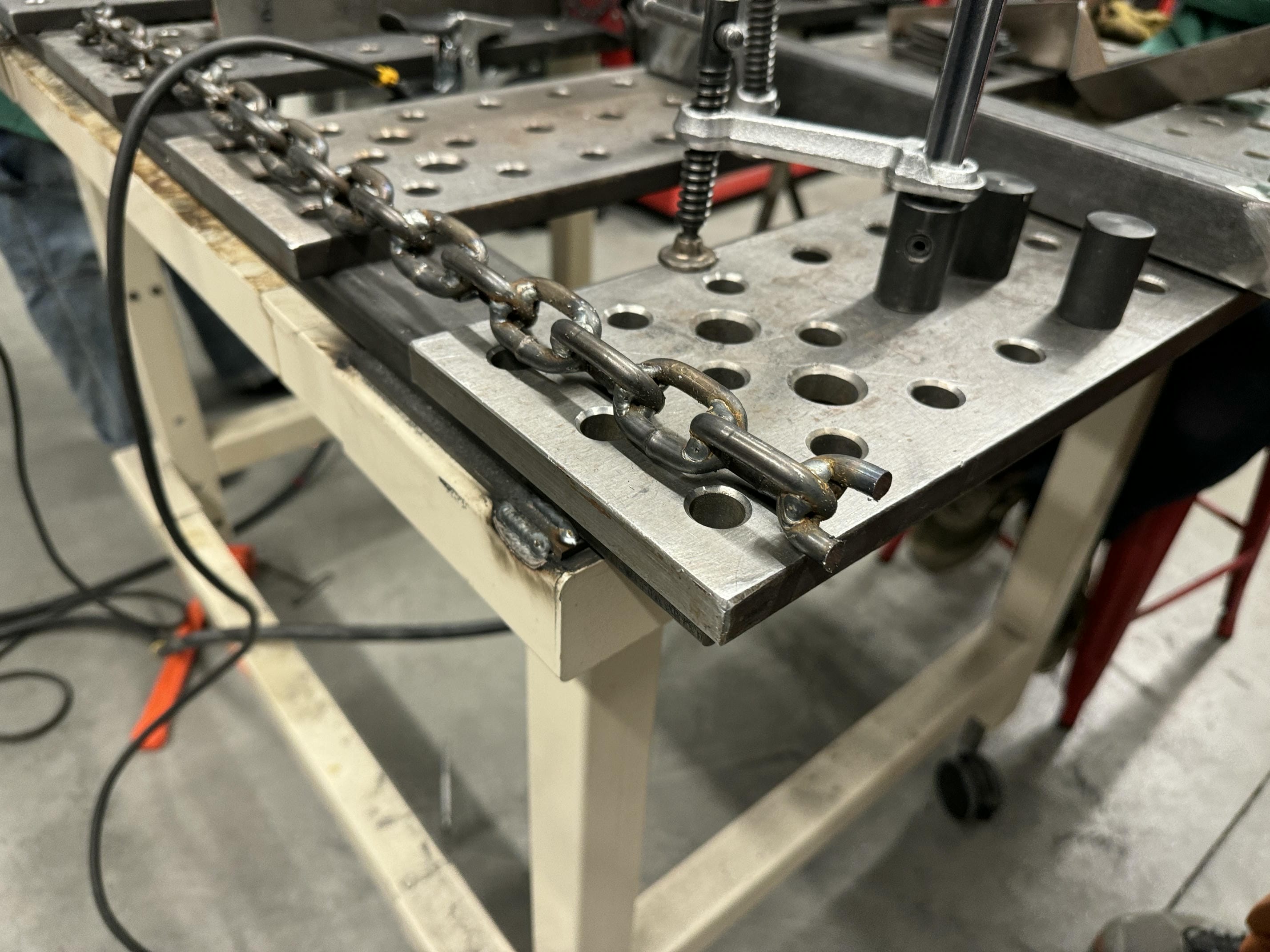

I spot welded the chain so that it was one rigid piece which could hold the load of the tabletop, then cut the first and last loops using a handheld horizontal bandsaw. For the actual tabletop, I used several pieces of plywood which my girlfriend glued together and secured with two crossbeams. In order to fix the chain legs to the table, I drilled holes through steel plates and welded the chain perpendicular to it. I then fixed it to the wood using wood screws. Finally, I welded the other end of the chain to the steel base.

For finishing, I took a chisel and hammer to remove small blobs caused by sparks during welding. I wire brushed the steel to remove oxidation, and applied a coat of patina and wipe-on polyurethane to prevent rusting. Here is what the final table looked like!