Automatic snail feeder

- CategoryFor fun

- Project dateJanuary 2024

- Skills requiredAdditive manufacturing, CAD, Arduino

- Github repository

About this

My lab, the MIT Sea Grant, has three pet snails who are supposed to eat two algae thins every four days. We've had issues in the past where we would forget to feed them for 8 days, or accidentally feed them more than we should've because we didn't communicate when we fed them. I looked into buying an automatic feeder, but when I looked it up, I found that all the off-the-shelf fish feeders were geared towards fish flakes, not algae thins, and instead of being programmable to feed every few days, they expected you to feed your fish several times each day. So, I thought, what the heck, let's just make one instead.

I first created a mockup of the assembly in Onshape. I had initially envisioned a Pez-dispenser style machine, which loads all of the algae thins in a spring-loaded stack and then dispenses them at the bottom. But then I considered that the algae thins are pretty brittle, and if it broke apart inside the machine, it would be annoying to clean out all of the previous thins to fix it. So instead, I decided to pivot to a revolver mechanism. A servo would rotate the revolver around, and one of the slots would have a hole, allowing the thins to fall down into the tank. Each chamber of the revolver would hold two algae thins, and with eight chambers, you would only need to refill the feeder once a month.

I included a lip on the lid for a transparent acrylic top so that you can see at a glance how full the feeder is without needing to open it. I made the acrylic piece a press fit into the 3D print so there was no need to use glue.

And in order to make removing the lid quick and easy, while still keeping it secure, I added a rotating locking mechanism into the cylindrical piece and lid. The round nubs of the lid would thus slide into these channels and rotate around and down

to secure it into place. I could've done threads instead, but printing threads in a deposition printer is pretty tough, and I wanted removing the cap to be quicker than unscrewing.

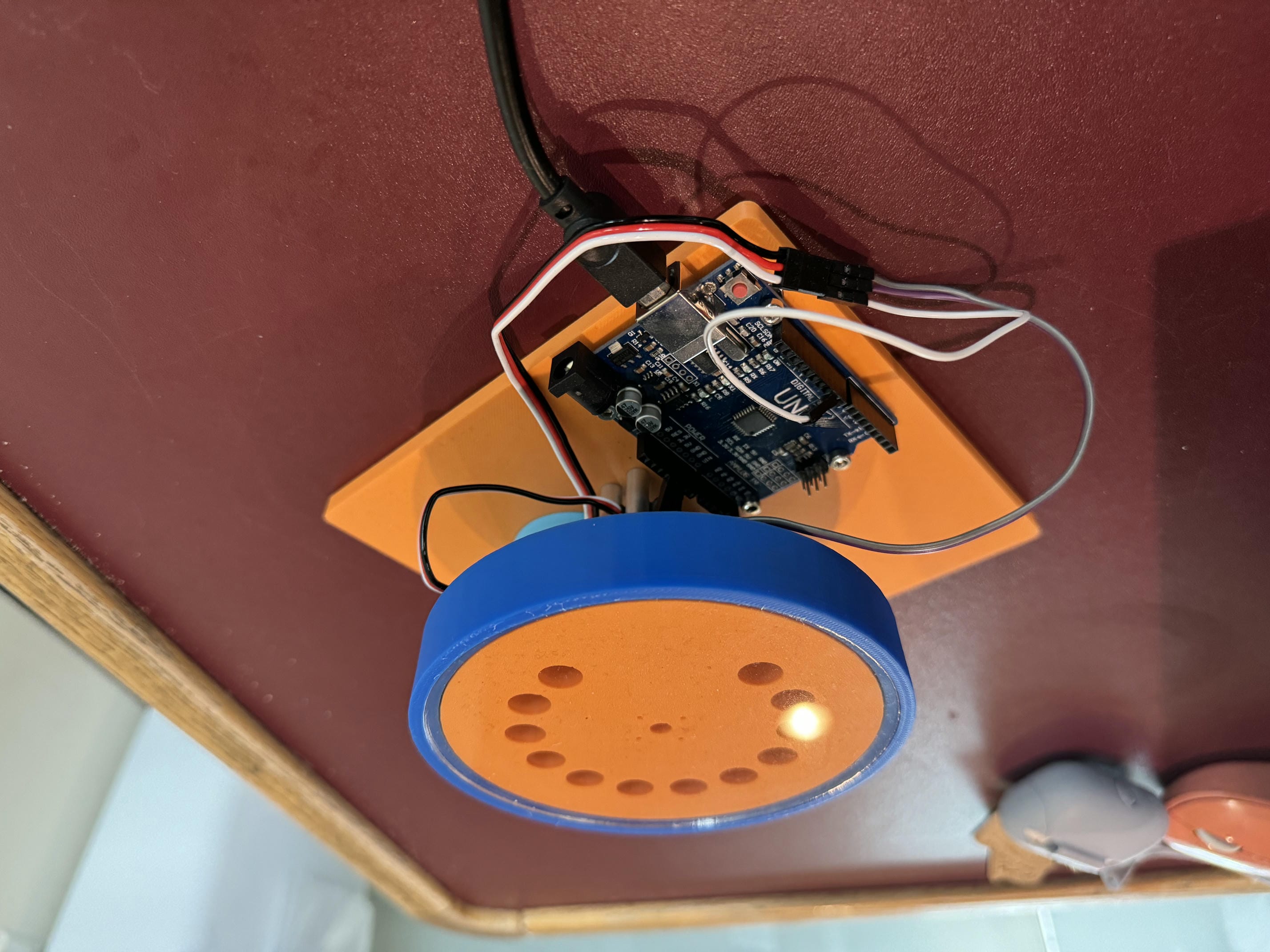

The servo is fixed to the base using standoffs, and the stationary plate below the revolver is attached to the servo at the same mounting points. After 3D-printing and laser-cutting all the pieces, I was ready to assemble. Here is what the final assembly looked like!

I wrote up some Arduino code to count down every four days and turn the servo the correct amount such that it would drop the algae discs.